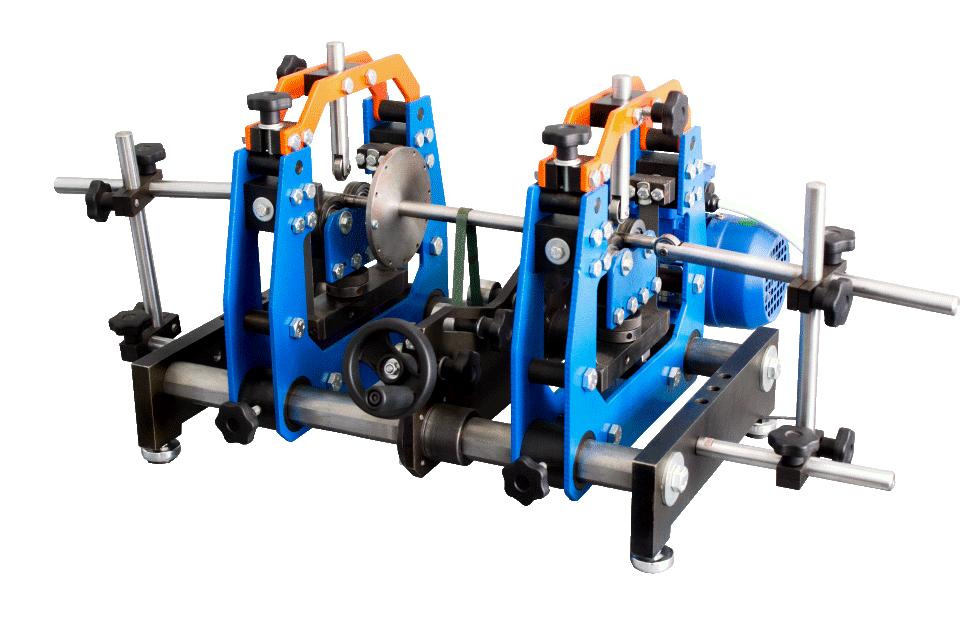

1. LINE OF RESONANT BALANCING MACHINES STB CARRYING CAPACITY FROM 5 UP TO 100 KG.

Our strategy is to combine the balanced constructivism of the mechanical system with the maximum use of modern technologies and algorithms in the measuring unit..

The new approach has allowed us to offer you reliable, convenient and easy-to-use balancing equipment with guaranteed high accuracy.

| № p / p |

Technical specifications | Parameter value | ||

| STB-5 | STB-20 | STB-100 | ||

| 1 | Carrying capacity, kg | 0,05-5 | 0,2-20 | 1-100 |

| 2 | Minimum achievable residual specific unbalance, g · mm / kg |

1 |

||

| 3 | Maximum rotor diameter, mm | 200 | 350 | 1100 |

| 4 | Maximum distance between supports, mm | 200 | 400 | 1350 |

| 5 | Diameter of rotor bearing journals, mm | up to 20 | up to 22 | 20-180 |

| 6 | Pause type |

Zarezonanasnyj |

||

| 7 | Support surfaces |

Rollers (sliding supports optional) |

||

| 8 | Drive speed range, from-1 (rpm) |

5-50 (300-3000) |

||

| 9 | type of drive |

Belt |

||

| 10 | Balancing system of the machine |

VBK series devices 2.1 |

||

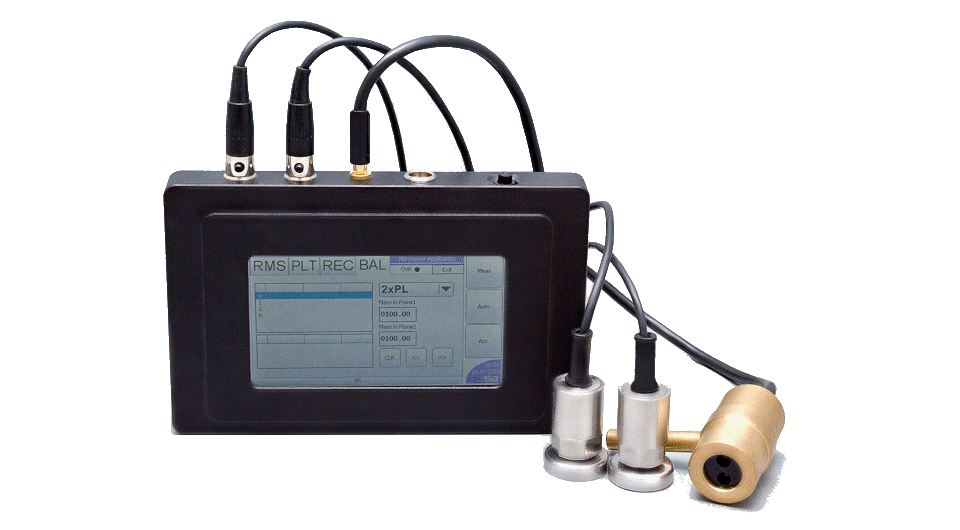

2. DYNAMIC BALANCING IN ITS OWN SUPPORTS.

For dynamic balancing in own supports, universal vibration analyzers VDK can be used 2.1 and VDK 3. These devices provide simultaneous processing of several input signals, equipped with phase markers and have the necessary software. Can also be used in balancing machines.

| Characteristic / designation | VDK series devices 1.2.1 | VDK series devices 1.2.1L | VDK series devices 3.3.2 | VDK series devices 3.3.2L |

| Number of measurement channels | 2 | 2 | 3 | 3 |

| vibrations: | 1 | 1 | 2 | 2 |

| revolutions | 1 | 1 | 1 | 1 |

| Command Entry Method |

Touch screen + buttons * |

|||

| Display size | 3.2 | 3.2 | 4.3 | 4.3 |

| Connection of vibration transducers: | VD001 | VD6, VD5 | VD001 | VD6, VD5 |

| Vibration acceleration measurement frequency range, Hz | (5*)10-10 000 | (5*)10-1000 | (5*)10-10 000 | (5*)10-1000 |

| Vibration velocity measurement frequency range, Hz | (5*)10-10 000 | (5*)10-1000 | (5*)10-10 000 | (5*)10-1000 |

| Vibration displacement measurement frequency range, Hz * | (5*)10-1000 | (5*)10-1000 | (5*)10-1000 | (5*)10-1000 |

| Measurement range of vibration acceleration amplitude, m / s2 |

50, 160 |

|||

| Frequency step in the spectrum from 10Hz to 1000Hz, Hz no more | 0,77 | 0,77 | 0,62 | 0,62 |

| Frequency step in the spectrum from 10Hz to 10000Hz, Hz no more | 16 | 16 | ||

| Averaging time, ed | 1, 4, 8 | 1, 4, 8 | Set by oper. | |

| Determination of the root mean square value of the measured vibration (SKZ) |

Vibration acceleration Vibration speed Vibration displacement |

|||

| Memory size for storing results, GB | 4 | 4 | 4 | 4 |

| The limit of the intrinsic relative measurement error of vibration acceleration in the frequency range from 10 up to 1000 Hz, % | ±5 | ±5 | ±5 | ±5 |

| The limit of the intrinsic relative measurement error of vibration velocity in the frequency range from 10 up to 1000 Hz, % | ±5 | ±5 | ±5 | ±5 |

| Availability of outputs for interfacing with a computer |

Using a USB cable 2.0 |

|||

| Instrument power supply |

battery 3,7 AT |

|||

| Overall dimensions of the device LxWxH, mm | 130x90x30 | 155x100x20 | ||

| Mass of the vibroanalyzer, not more than, kg | 0,6 | 0,8 | ||

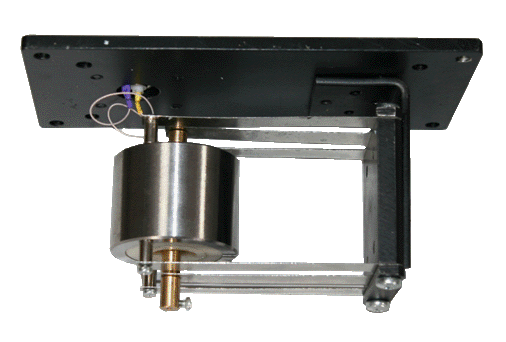

3. MODERNIZATION PROGRAM FOR BALANCING MACHINES IN SERVICE

The aim of the upgrade is to improve balancing accuracy combined with increased productivity.

Increased accuracy is achieved through the use of the latest components and technologies in the production of measuring transducers and special algorithms for processing measurement information, allowing to qualitatively highlight the informative signal.

Increased productivity with convenience and responsiveness, clarity and simplicity of the interface using the touch screen.

The complex for the modernization of balancing equipment includes:

- drive with control unit;

- velocimeters (vibration velocity sensors) and / or accelerometers - 2 PC.;

- phase marker;

- computing complex.

4. VIBRATION TRANSDUCERS FOR BALANCING MACHINES.

Velocimeter - high precision contact sensor

The active accelerometer has increased sensitivity and noise immunity of the communication channel due to the presence of a built-in charge amplifier.