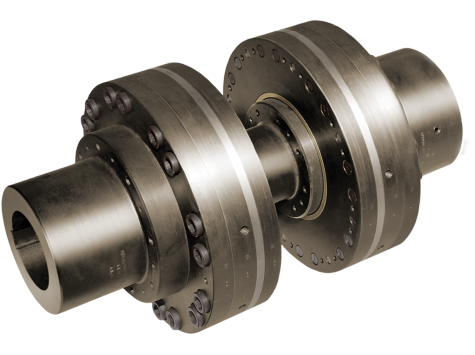

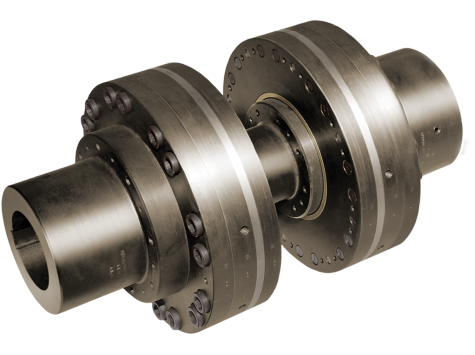

COUPLINGS TYPE MUP 2

MUP (elastic plate coupling) is designed for the most critical machines and units of the oil and gas industry and energy, including nuclear energy. The elastic element of the “disk” type provides it with several important advantages:

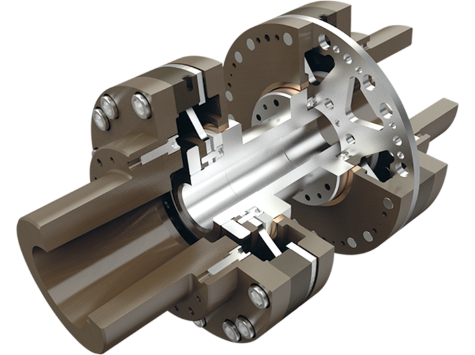

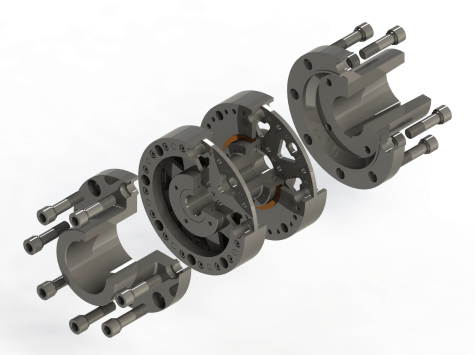

- When the elastic element is destroyed due to increased loads, associated with abnormal situations in the connected machines, rotation transmission stops. The design of the coupling ensures safe run-down of the machines rotors after actuation of the automation system, and also protection against sparking and “overhang” of the middle part of the coupling (spacer). Thus, the MUP coupling can perform protective functions and prevent large-scale consequences of emergency.

- Coupling MUP has a stable characteristic of axial force dependence on the magnitude of the shafts axial displacement, This characteristic practically does not depend on the transmitted moment, and also guarantees the reliability of detuning from the axial resonances of the spacer. This characteristic is also important in some particular cases of the machines layout, such, as the absence of thrust nodes in large electric motors, It also ensures reliable de-alignment of the spacer axial , resonances, which some industry standards require.

Allows using in hazardous and explosive fire-hazardous areas of class B-1a and B-1g according to the "Rules for the Installation of Electrical Installations", in which the formation of an explosive mixture of category IIA-T3 according to GOST 12.1.01-78.

SPECIFICATIONS

|

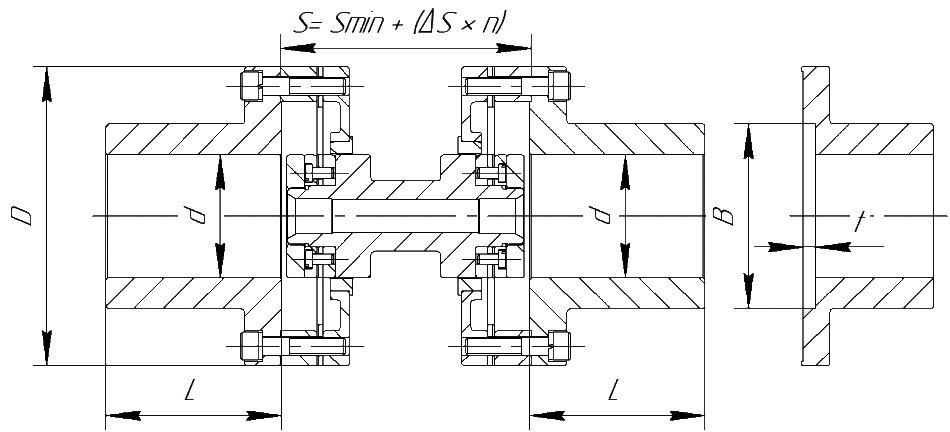

MUP-2 - dimensions |

|||||||

| Coupling nominal size | Standard length of coupling half L, mm | Coupling outer diameter D, mm | The minimum distance between the ends of the shafts Sme, mm | Bore diameter of half-couplings dmax, mm | Transmission unit weight | Weight of unbored coupling half standard, kg | |

| at Sme, kg | +ΔS = 10 mm, kg | ||||||

| MUP 2-17 | 80 | 125 | 110 | 60 | 4,1 | 0,08 | 3,9 |

| MUP 2-34 | 100 | 150 | 125 | 70 | 5,6 | 0,08 | 8,2 |

| MUP 2-67 | 120 | 170 | 130 | 80 | 9,7 | 0,08 | 10,7 |

| MUP 2-105 | 140 | 190 | 130 | 95 | 13,3 | 0,13 | 15,7 |

| MUP 2-210 | 150 | 220 | 150 | 110 | 16,5 | 0,13 | 17,3 |

| MUP 2-420 | 160 | 265 | 165 | 135 | 31,8 | 0,31 | 28,0 |

| MUP 2-670 | 180 | 290 | 175 | 150 | 40,0 | 0,31 | 33,0 |

| MUP 2-850 | 200 | 295 | 190 | 150 | 46,0 | 0,26 | 39,0 |

| MUP 2-1340 | 200 | 320 | 200 | 160 | 57,0 | 0,49 | 52,0 |

| MUP 2-2100 | 200 | 365 | 240 | 180 | 82,0 | 0,54 | 56,0 |

| MUP 2-2700 | 220 | 385 | 250 | 200 | 92,0 | 0,57 | 65,0 |

*Transmission unit length S performed, starting from size Smin and more in steps ΔS = 10mm., other sizes depending on the distance between the shafts are available on request. Length of half couplings L may differ from the standard, subject to filling out the questionnaire. dimensions AT and t pockets for fastening the coupling half with a nut are provided upon request when filling out the questionnaire.

Note: To determine the mass of the coupling assembly, it is necessary to add the mass of the two coupling halves with the mass of the transmission unit.. If not specified, the size of the cylindrical bore of the half couplings is made with an accuracy of H7 and the keyways Js9 are made according to DIN standards 6885.

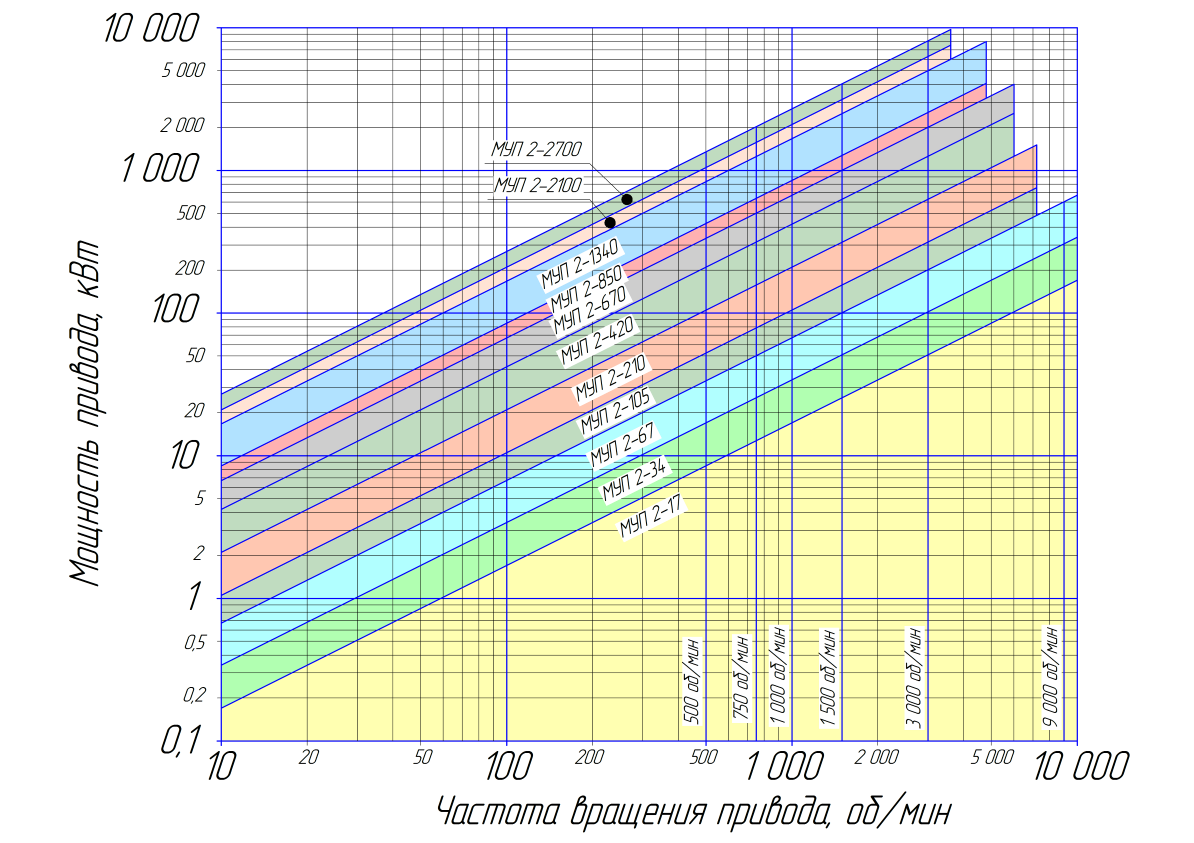

| MUP-2 - technical data | ||||||||

| Coupling nominal size | Specific power kW / 1000rpm | Torque, Nm | Maksim. turnovers, rpm | Maksim. revolutions without balancing, rpm | Max. axial displacement | Max. radial displacement, ±мм | ||

| Nominal, Nm | Peak overload, Nm | ± mm | Equivalent. an effort, n | |||||

| MUP 2-17 | 17 | 160 | 395 | 18000 | 10000 | 1,5 | 650 | 0,25 |

| MUP 2-34 | 34 | 315 | 787 | 15000 | 8500 | 1,7 | 720 | 0,30 |

| MUP 2-67 | 67 | 630 | 1575 | 13000 | 7500 | 2,0 | 800 | 0,35 |

| MUP 2-105 | 105 | 1000 | 2500 | 12000 | 6500 | 2,2 | 1500 | 0,40 |

| MUP 2-210 | 210 | 1950 | 4875 | 10000 | 5500 | 2,4 | 3050 | 0,45 |

| MUP 2-420 | 420 | 4000 | 10000 | 8500 | 4600 | 2,6 | 4600 | 0,50 |

| MUP 2-670 | 670 | 6300 | 15750 | 7500 | 4200 | 3,4 | 5700 | 0,60 |

| MUP 2-850 | 850 | 8050 | 20125 | 7500 | 4200 | 3,4 | 7800 | 0,60 |

| MUP 2-1340 | 1340 | 12500 | 31250 | 7000 | 3800 | 3,8 | 9600 | 0,60 |

| MUP 2-2100 | 2100 | 19500 | 48750 | 6000 | 3400 | 4,0 | 10100 | 0,60 |

| MUP 2-2700 | 2700 | 25650 | 64125 | 5800 | 3200 | 4,0 | 12500 | 0,60 |